Safety is one of the most important reasons for purchasing a data center lift. Some facilities may try to use warehouse lifts rather than purpose-built lifts designed specifically to transport, install, and uninstall IT equipment in data centers. Using the wrong type of lifts may cause employee injuries, damaged equipment, wasted time, and shorter equipment lifespans.

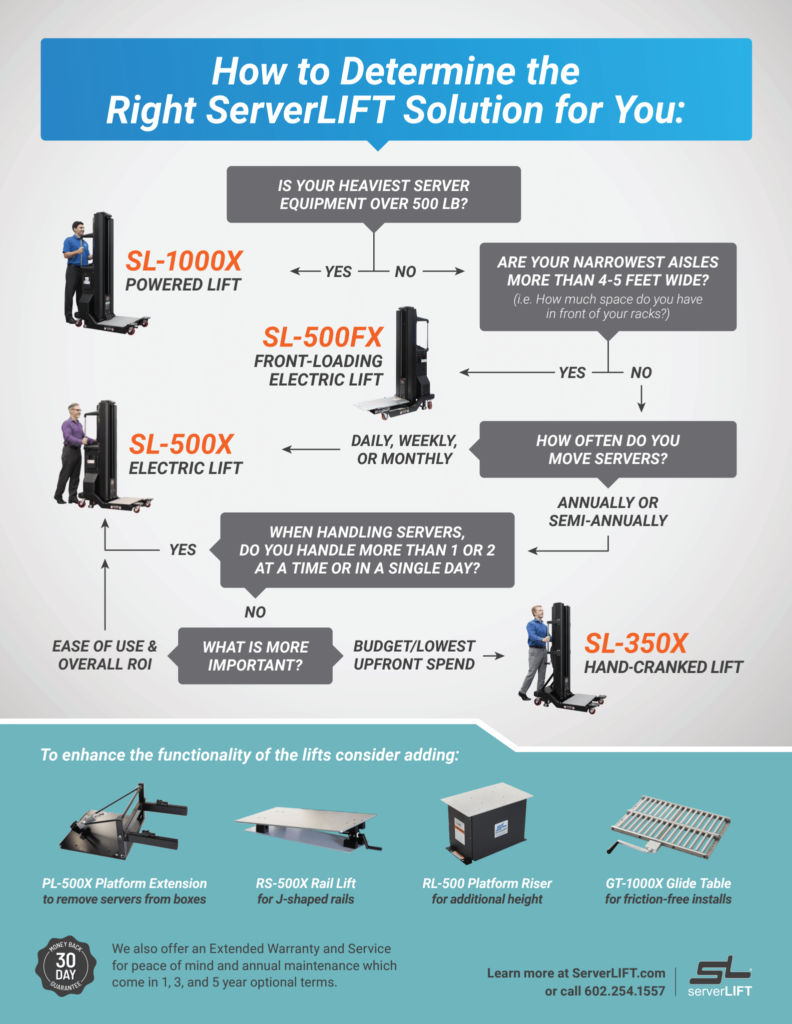

Choosing the correct server-handling device to lift and move heavy servers and other rack-mounted data center equipment requires research and due diligence. Data center managers should be careful about choosing the first device they come across—or the cheapest—expecting it to perform well and prevent costly accidents.

It is also important to factor in the time saved, the injuries prevented, the damage avoided, and the superior lifespans of IT equipment that has been handled properly. The cost of a dedicated server-handling device would be negligible compared to the savings gain. The upfront cost in the right data center lift will always be worth the return on investment gained over time.

It pays to take time, research heavily, and make a sound decision on which data center lift is best for the data center facility. The following tips will help managers choose a new server-handling device wisely and ensure many years of successful, safe operation.

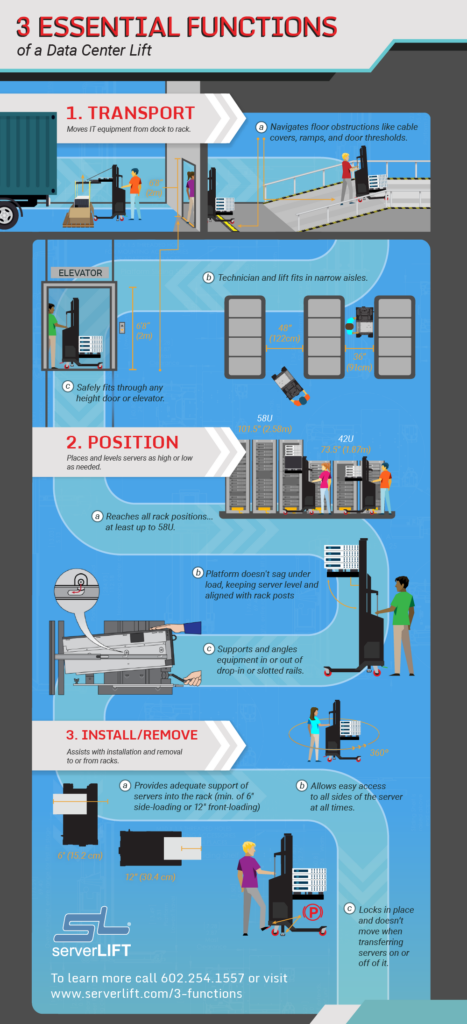

1. Choose a server-handling device that performs all essential functions safely.

Just because an internet search presents results of lifts that are advertised for use in the data center, doesn’t mean those devices are actually suitable for data center use. Some warehouse lift manufacturers market to data centers, even though their products lack the safety features and functions necessary for a proper data center lift.

Most material lifts are designed for warehouse or construction use. For those applications precision isn’t required, so it’s fully acceptable that their platforms sag under load, just like a forklift. But between narrow aisles of a data center, using such a tool makes aligning their payloads with the precision needed to affix to the rack nearly impossible. Their small wheels make passing over grated, raised flooring and ramps challenging at best. They may even get caught on the grates and “push back” on the operator when encountering a ramp, increasing the chances of equipment damage or operator injury. And, because they typically lack any or adequate braking features, expect them to move and roll when pushing a server on or off the platform. Many material lifts also tend to have hydraulic lifting mechanisms and several pinch points that lead to unsafe operation in the close quarters of a data center.

For all these reasons, it is crucial to understand what a data center lift should be able to do before purchasing one.

Look for a lift that:

- Can navigate carefully in narrow aisles, easily around tight corners, and smoothly over uneven flooring and grades

- Has lock-down brakes, and safe lifting mechanisms

- Does not have dangerous pinch points that could catch and/or injure employees standing too close or wrestling with equipment

- Maintains enough rigidity to keep the payload platform level for precise alignment with the server rack shelves to avoid the need for manual lifting and prevent sharp drops

2. Decide between a motorized or a manual lift.

Motorized and manual data center lifts can both be capable pieces of machinery that will save your back by getting the job done without manual handling—safely and efficiently. The main difference between them is that motorized lifts eliminate any physicality in the process of lifting the equipment, while manual lifts require operators to strain their arm and shoulder to hand-crank the platform up or down. Both are potential options, but motorized lifts are far and away the safest, least physical tools (and therefore the best-practice method), needed for any data center operation.

If techs only move one or two rack-mounted servers or other heavy equipment around a few times a year, manual data center lifts are still not the first, best choice, but they can be a great alternative option. They’ll allow employees to migrate equipment from one area to another safely, while fulfilling the requirements of the safety department.

But, most data center operations require frequent (daily, weekly, or monthly) migrations and rearranging of equipment, or tend to handle multiple servers in a single day. In these cases, a motorized lift is both the first and only choice.

Motorized lifts are easier to use, more efficient, and eliminate any musculo-skeletal strain associated with handling servers or hand-cranking a lift winch repeatedly. Analyzing the monthly load in terms of equipment weight and the frequency of moves will help determine whether a manual lift is a possibility, but, in any case, a motorized lift is always going to be a better fit for the facility, equipment, and employees. When choosing a motorized lift, look for one that has a high-capacity motor, a fully sealed, leak-proof, deep cycle battery for all-day use, and can be charged on any power voltage source (wall outlet or from the rack) in the facility.

3. Double-check the payload weight limits of your top lift candidates.

Servers can weigh up to hundreds of pounds. If a data center primarily has small IT equipment, with one or two heavy items, a manager might believe that a lightweight data center lift will be sufficient for most purposes within the facility.

However, this logic may be flawed. The heaviest IT equipment still needs to be handled safely. Moving heavy servers only once or twice per year, those occasions may still result in injury and damage if the lift isn’t up to the job.

It’s best to choose a lift that can handle the heaviest piece of IT equipment in the facility or that might be acquired down the road. If that means choosing a lift rated for 700 pounds even if the facility only has one switch or blade server chassis that weighs that much, that is better than selecting a server-handling device that’s not capable of moving the heaviest—and most dangerous—piece of equipment safely.

Heavy-duty lifts also pay for themselves because they increase efficiency. With them, you can stack and rack several smaller, lighter servers all at once. Plus, just one major migration can make a high-capacity data center lift worthwhile. The migration can be done safely and efficiently, sometimes in a fraction of the time it would take to move everything manually or with a lighter-capacity lift.

4. Make sure the lift can reach from the floor to the top of the tallest rack in the data center.

A lift that can’t reach the highest and lowest points where IT equipment needs to be placed is ineffective.

Data center technicians are just as prone to dropping heavy loads and injuring themselves or damaging IT equipment when they are moving items at floor level and above their heads. Additionally, the ever-increasing demand for high-density spaces within data centers means that servers and other IT equipment are being stacked higher than ever in some places. Therefore, it’s critical to choose a server-handling device that can lower all the way to the floor and reach the highest rack in the facility.

Moves and migrations aren’t the only reasons to have a data center lift. Anytime an employee needs to unpack a new delivery and lift it off the floor or from a pallet, a dedicated server-handling device can make the process much easier, faster, and safer.

5. Check all applicable regulations.

The data center itself will surely have safety and quality regulations that must be met for bringing new server-handling devices into the building. Similarly, local, regional, state, and even federal regulations may dictate which types of devices are or are not appropriate for data center lifts.

Data center managers should first check which jurisdictions cover the use of server-handling devices and then research what the guidelines for lifts are within those jurisdictions. For example, the EU requires a CE certification for all equipment, and many jurisdictions in the United States require FCC compliance to ensure that any electronic devices don’t interfere with sensitive equipment nearby.

ServerLIFT is happy to help data center managers choose the perfect server-handling device.

Here at ServerLIFT, biztonság is at the core of everything we do. We believe deeply in not only cultivating a strong, durable culture of safety within data centers, but also in providing server-handling devices with the most extensive and carefully engineered safety features in the industry. A data center lift needs to be both mechanically and electromagnetically safe for use. Our server-handling devices are compliant with or certified to standards recognized around the world. We maintain a number of global certifications including those from UL, CE, FCC, KCC and IC.